Home / About BAYLISS BOATWORKS / News / Latest News / Timeless Interiors

Timeless Interiors

Posted August 10, 2020

We pride ourselves on the fact that our Bayliss custom yacht interiors are some of the most striking in the industry. It is important that the quality of the materials and the functionality and execution of the design ultimately shine through.

Although the appearance of a custom Bayliss yacht interior looks clean and simple, the smallest details set it apart, from pullman bunks to actuated parts, to veneer placement on the drawer faces. Bayliss Interior Carpentry Supervisor, Bill Crum signs off on everything before it makes the cut.

“Some of the details we’re known for are our margins, grain matching, and veneer matching- inside and outside of every cabinet,” says Crum. “I think this attention to detail definitely contributes to the timeless appearance our boats are known for.”

ATTENTION TO DETAIL:

Approximately 8,000 to 16,000 interior carpentry man-hours go into each build, depending on the design. When asked about the installations he’s most proud of, Crum lists off a few. “On Singularis [now Reel Wheels II ], we resawed the 26-foot companionway board out of a teak boule. For Blue View, the way we blended the spiral staircase to the crew staterooms into the hanging locker beside it. And on Blank Check , the book-matched galley floors.”

On every interior, our Interior Carpentry crew utilizes a technique called book-matching. This is the practice of matching two wood surfaces, so that the adjoining grain surfaces mirror each other, giving the impression of an opened book. From starboard to port, the window frames, valances, and even horizontal veneers are book-matched.

“If someone is detail oriented, we’re their guy,” says Bayliss. “If we cut corners, it would stick out like a sore thumb to us.” Each Bayliss door, cabinet and drawer is a trove of the details we’re known for: our custom Bayliss dovetail joint design, grain matching and solid wood edge banding.

Even the hardware on drawers must pass the test. “You can feel the quality under your fingertips,” says Bayliss. “It’s crisp and smooth.” Vertical integration throughout our company helps us build better interiors. For instance, the Bayliss Boatworks Metalworks department collaborates with our Interior Carpentry crew to build our own proprietary custom television-lifts, pullman bunks, and hidden door hardware in order to provide our boats with components that are functional and stand up to the punishment offshore waters can deliver.

MATERIALS AND SELECTIONS:

Selecting wood samples seems easy enough but we do things a little differently. We begin each custom yacht interior with a conversation about the owner’s desired wood choice, quality, and color, then make a rough calculation of the log size we’ll need to complete their vision.

We use one log for the entire boat on each build in order to ensure grain consistency. No two trees are the same; there are variations in every species that yield remarkable differences that we can tailor to an owner’s requirements. Finding quality logs that are big enough to compensate for this technique can be an extensive search. Once the logs are secured, we generate samples for the owner using both clear finish and stains for their approval.

The veneers are one important component of Bayliss custom yacht interiors, but the dimensional solid stock lumber is equally as important. We always use solid boards for all cabinet tops and bunk rails, and these pieces must match the feel of the interior quality. To reduce the weight and increase the structural stability of our cabinetry, we also use Tricel panels in the fabrication of our interior components, where possible.

Bayliss yachts are known for their excellent resale value. This wouldn’t be the case without Bayliss custom yacht interiors that stand the test of time, both in durability and aesthetics.

“When you choose teak for your interior wood choice, you never have to apologize for it. It’s an accepted standard,” says Bayliss. “However, recently there has been a lot of interest in walnut as an interior wood choice.”

Walnut is also very high quality and offers a lot of possibilities similar to teak. Both teak and walnut, when coupled with high quality workmanship and a flawless finish, are excellent choices.

Whatever the wood choice, to protect this living art, interior surfaces receive exterior quality finish with UV prohibitors. “We’ve chosen to utilize an exterior quality interior finish that requires 15-18 coats,” says Bayliss. “Obviously, there are less labor-intensive options out there, but this finish truly stands the test of time.”

ADVANCEMENTS:

“We’re in a constant state of evolution,” says Bayliss. “We are always refining previous tried and true techniques, making them better.”

The CNC (i.e., Computer Numerical Control) machine has been a real game-changer. It has sped up our fabrication process by changing the way we’re capable of making cuts. The Digital Fabrication & Design Department cuts all doors, frames, small parts, and nesting items using the CNC machine.

In addition to the CNC machine, we have converted a sawmill into a resaw in order to provide more latitude when it comes to book-matching, and specialty pieces. We now do a tremendous amount of resaw work in-house.

Each of our twelve Interior Carpentry crew members has his own strengths. During brainstorming sessions on the interior layout of a new build, ideas come from every person on the team.

The crew, led by Crum, is trusted to come up with a design concept, then collaborate with the owners and our Digital Fabrication & Design department to make it truly special.

“The creativity of those guys,” Bayliss says, shaking his head in wonder. “Their excitement in achieving the highest quality is infectious and really drives all of us.”

In the News Sequentis (Bayliss 60′) Delivered

Fall fishing for tarheel and mama seata, more than maintenance.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

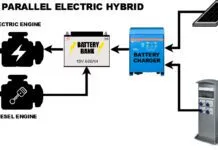

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Catalina 42 Mk I and Mk II

Beneteau First 42s7 Used Boat Review

Pearson 303 Used Boat Review

Grampian 26 Used Boat Review

Special Report: How to Prevent AIS and VHF Antenna Malfunction

Vesper Marine WatchMate 850 and Icom M91D: Where Credit is Due

How to Create a Bullet-Proof VHF/SSB Backup

Tips From A First “Sail” on the ICW

Haul Out Tips to Avoid Confusion and Delays

Checking Rope Strength

Lashing for Strength

Are Wrinkles Killing Your Sail Shape?

Ensuring a Safe Space for Batteries

Impact of Modern, Triangular-Design on Boat Performance

Keel and Rudder Design Basics

Diesel-Electric Hybrids Vs. Electric: Sailing’s Auxiliary Power Future

Wooden Boat Revival: Can Boatbuilding Be Regenerative?

How to Make Dodger Cover Canvas Pattern

How Much Does It Cost to Keep a Boat on the…

Insurance For Older Sailboats

PS Advisor: Acid Cleaning Potable Water Systems

Product Hacks: Velcro, Bounce, Anti-Skid Mats and Pool Lights

Stopping Holding-tank Odors

Giving Bugs the Big Goodbye

Five Best Cheap Clothing Options for Cold-Weather Sailing

How to Scuba from Your Boat

Compact Scuba Kits for Sailors

Cold Weather Clothes to Extend the Sailing Season

Bilge Pump Installation and Maintenance Tips

Full-Time Ocean Trash Cleanup in the Arctic Circle

Boats That Fly? How High Tech Rocked the America’s Cup

R. Tucker Thompson Tall Ship Youth Voyage

On Watch: This 60-Year-Old Hinckley Pilot 35 is Also a Working…

- Boat Maintenance

Maintenance of Interior Teak

Nevertheless, the simplicity of finishing teak, the economy of a single variety of wood in inventory, and the ready acceptance by boat buyers, are all attractive reasons why boatbuilders use the wood for interior decor.

With resistance to weathering as its primary virtue, however, teak makes less sense for use as trim below. Nevertheless, the simplicity of finishing teak , the economy of a single variety of wood in inventory, and the ready acceptance by boat buyers, are all attractive reasons why boatbuilders use the wood for interior decor .

Typically, only the most expensive boats have interior teak that is varnished, usually with a satin-finish varnish for a “hand-rubbed” effect. Such a finish should last for years if it is not abused or allowed to get wet. Maintenance can be no more than an occasional wipe with furniture oil or polish and another coat of varnish every decade or so.

Many boatowners wonder if it would be worthwhile to varnish the oiled teak trim in a typical production boat in order to take advantage of the easiermaintenance. From the standpoint of reduced maintenance, the answer is, “probably not.” At least three coats of varnish would be required (a Hinckley, for example, has six to eight). The time required to prepare the surfaces, and to sand and varnish the trim in a 30-foot production boat, could amount to a full winter’s work. In fact, it is quite likely that the total amount of work would be more than the amount of effort required to maintain the oiled teak trim over the lifetime of the boat.

On the other hand, from the standpoint of aesthetics, a varnished interior has much to recommend it. After all, such an interior may be the best way to upgrade your boat’s interior to resemble a Hinckley or a Swan. Of course, if the wood is anything but teak, the question is moot; oak, mahogany, butternut, birch, and ash must be protected with varnish, preferably with an epoxy sealer underneath.

The quality of the interior finish varies widely among boatbuilders. Some builders leave teak rough and bare, others (curse them) rough and oiled, and still others (to their credit) make a real effort to sand the wood smooth and oil it carefully. Despite the variation, however, almost any production boat with teak below can benefit from a reasonable amount of time and energy devoted to improving the look and feel of the wood.

Preparation The key to finishing joinerwork is to start with a smooth surface, and that, of course, means sanding. Even some of the better boatbuilders sometimes deliver boats with trim that is only as smooth-or as rough-as it comes out of the planer. Others may simply have a helper give the interior trim a swipe or two withapieceof sandpaper thedaybefore theboat is delivered. Well-finished joinerwork apparently costs more in labor than can be added to the price of some boats.

Fortunately, the boatowner can often take up where the builder left off with a minimum of difficulty. Before applying oil or varnish, sand the wood in the direction of the grain with the finest sandpaper that smooths it with a reasonable amount of effort; 120-or 150-grit should be about right. Oiled wood that is rough will take coarser paper and more work, since the oil both darkens and hardens the surface of the wood.

Avoid the use of power sanders, except possibly a high-speed palm sander, in order to prevent scars and swirl marks. Finish sanding should always be done by hand with 220-or even 240-grit paper for a first-class job. Again, be careful to sand in the direction of the grain and to get into tight corners.

At this point, your investment may be such that you actually consider a varnish finish (but sleep on the notion). Preparation of the wood is more than half the work of applying an oiled finish, but this preparation is only just the first step for a varnished interior.

Varnishing Interior Trim If you do decide to varnish, give the wood a final sanding with fresh 240-grit paper (or whatever is specified on the varnish can> for an extra measure of satisfaction and smoothness. Then, give the wood at least three coats of varnish; five is better, especially in high-traffic areas.

Belowdecks, there is no need to use a marine varnish with an ultraviolet inhibitor. We suggest a good-quality polyurethane varnish such as ZipGard. We have found that polyurethane varnishes are durable, economical, easy to apply, and fast drying. A second coat can often be applied in two to three hours.

Varnish with a high gloss shows every surface irregularity, tends to hide the grain of the wood, and sometimes reflects light in an objectionable manner. For these reasons, we prefer a semi-glossor satin-finish varnish which simulates a hand-rubbed surface. The traditional method for producing a hand-rubbed finish is to first rub down the final coat with powdered pumice applied with rubbing felt and water. This is followed by rubbing with rottenstone and linseed oil applied with a soft cotton cloth. Some of the modem rubbing compounds available at your local hardware store are considerably easier to use, however. We have used Duffy’s Elbow Grease with good results. This is a Vaseline-like grease which is used with 0000 bronze wool. (The instructions call for steel wool, but tiny bits of steel wool inevitably end up rusting in a marine environment.)

Whether using pumice and rottenstone or one of the newer greases, the object of hand-rubbing is to rub out all the dust sediment, brush strokes, rough spots, and hairs. Hand rubbing produces a beautiful finish, but it is a lot of work. Try it on a small piece like a sextant box before deciding to hand-rub the entire interior. Better yet, use a satin-finish varnish.

If you choose to varnish interior wood, we suggest that you avoid the use of waxes and furniture polishes on the finish. Modern polyurethane varnishes are so hard they do not need the additional protection of wax. Moreover, wax complicates any future recoating with varnish, in that all traces must be sanded or washed off in preparation for revarnishing. With a thick enough varnish finish, only a damp cloth should be needed for routine maintenance and cleaning.

Oiling Interior Trim If inclination and inertia tell you not to varnish but rather to finish the wood with an oil or dressing, choose a top-quality furniture oil. These are usually linseed oil- or tung oil-based, both of which seal the grain of the wood and harden the surface over time. One major difference between linseed oil and tung oil is that linseed oil tends to darken more than tung oil as it oxidizes; otherwise they share essentially the same virtuous characteristics. Incidentally, we would not use any of the teak dressings (including Deks Olje) intended for on-deck use. Most are high in penetrating solvents and low in oils and are not intended to produce a smooth surface on the wood.

Wipe on the oil liberally and rub it into the wood thoroughly. Use a polyfoam brush to apply the oil and a soft terrycloth pad to rub. A small amount of turpentine added to the oil (for the first coat only) should increase penetration. All traces of excess oil should be rubbed off; rub well into corners and crevices. Let the first coat dry for a day or two and follow up with subsequent coats. No excess oil should remain on the wood surface after the rubbing is completed; it will remain sticky, collect dirt, and may stain clothes and upholstery. After a day or so, if you find that the surface feels oily, give the whole surface a final hard rub with a clean piece of terrycloth dampened with turpentine.

Treatments for exterior teak are usually only available from marine outlets, but most neighborhood hardware stores carry a number of oils that are suitable for interior trim. We have used both Min-wax “hand-rubbed” effect oil and Watco Danish Teak Oil in the “original” finish on belowdecks teak, and have found them both to produce a pleasing and long-lasting finish. Both can also be used on interior mahogany trim if it is unvarnished. Lighter oils such as Scott’s Liquid Gold produce a nice finish and are easier to apply, but do not last nearly as long. These oils are better for an occasional sprucing up, rather than an original finish. A light coat of Liquid Gold, incidentally, does wonders for the appearance of bulkheads covered with the “wood-grain” plastic laminates such as Formica.

If you want an absolutely smooth finish, let the first few coats of oil harden for a few weeks, then apply another coat of oil and rerub. This time, however, use 600-grit wet-or-dry sandpaper or fine bronze wool rather than a terrycloth pad. Use the oil instead of water with the sandpaper as a “wetting agent” and continuously wipe away the residue with a clean cloth as you work.

Since wax will not adversely affect future coats of oil the way it would with varnish, you may want to apply wax or furniture polish to an oiled surface. A good quality carnauba paste wax such as Butcher’s Wax gives the surface a glowing patina that rivals a hand-rubbed varnish finish, and protects the wood from grease and dirt.

A Few Words About Other Woods Some of the most impressive-looking modem yacht interiors use light-colored woods such as ash, butter nut, spruce, and white oak for bulkheads and cabinetry. These woods pose problems that teak does not. Specifically, they are more liable to damage and discoloration from water. As a result, they must be well finished to prevent moisture from soaking into the wood.

Ash and oak are especially sensitive to water, almost instantly turning gray where they are exposed to a combination of air and water. This gray may be bleached out, but bleaching is a frustrating job and not likely to restore the wood to its original light yellow color. From the outset, even with a brand new boat finished in one of these woods, we would add a couple of coats of varnish wherever there is a chance that the wood may get wet. These areas include the area around the companionway, the deck hatches, the galley countertop, and berth risers close to the cabin sole. Also, plan to revarnish every couple of years or whenever there are signs of moisture penetrating into the wood.

Smooth, well-finished wood is easier to keep up than wood treated with low-effort finishes. An annual wipe-down with furniture polish should be enough, but watch for worn spots and water stains that may need some special attention.

Care of a Teak And Holly Cabin Sole The combination of teak “planks” and strips of holly has become a favorite of boatbuilders for cabin soles. The combination is handsome and looks “traditional,” even if its place in traditional boatbuilding is questionable.

Most teak and holly soles are just a thin veneer on a sheet of plywood. Left unprotected, the sole won’t last long, nor can it be easily restored. The thinness of the veneer and its location inside the cabin usually precludes the use of either a liquid teak cleaner or a power sander.

Unfortunately, there is no simple way to both assure protection for the wood, and to give a secure footing when the cabin sole is wet. Varnish suitable for protection does not have good nonskid characteristics.

Faced with this dilemma, we would use a satin-finish polyurethane floor varnish with just a small amount of nonskid grit (usually pumice or finely ground sand) added in areas such as the base of the companionway and outside the head, where wetness is apt to be a problem. And then don’t ignore the wear on the sole during annual maintenance; it may need an annual touching up with varnish.

RELATED ARTICLES MORE FROM AUTHOR

How much does it cost to keep a boat on the hudson river, new york, leave a reply cancel reply.

Log in to leave a comment

Latest Videos

24 Knot Speed Trimaran – The Dragonfly 40 Ultimate

AMAZING Sailboat Drones, US Navy Deploys 65 Foot Sailing Drone

The SHOCKINGLY Comfortable Million Dollar Sailboat From Moody

New Sailor CRASHES and Needs Advice!

Latest sailboat review.

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

IMAGES

COMMENTS

We custom build teak grates to patterns or specifications. Typical interior applications for our custom teak grates include showers, heads and bilge vents. We also sell notched and flat teak grating stock in 1" and custom thicknesses for builders fabricating their own teak grates.

Aug 10, 2020 · Both teak and walnut, when coupled with high quality workmanship and a flawless finish, are excellent choices. Whatever the wood choice, to protect this living art, interior surfaces receive exterior quality finish with UV prohibitors. “We’ve chosen to utilize an exterior quality interior finish that requires 15-18 coats,” says Bayliss.

We will secure samples and assemble a package that meets your design requirements. Our insight and experience as yacht carpenters and builders can aid in the flow from design concept to finished interior, and help you make the right choices. Maritime Wood Products offers architectural veneers of the very finest quality and workmanship.

Feb 2, 2011 · With resistance to weathering as its primary virtue, however, teak makes less sense for use as trim below. Nevertheless, the simplicity of finishing teak, the economy of a single variety of wood in inventory, and the ready acceptance by boat buyers, are all attractive reasons why boatbuilders use the wood for interior decor.

Welcome to Maritime Wood Products, the premium manufacturer of custom teak decks and the supplier of finest quality wood products for yacht building and restoration. We are specialists in wood and its application, and we look forward to the opportunity to serve you.

Bay Area Marine Services, the most trusted name in custom marine carpentry, specializes in custom boat interior cabinetry, restoration, cherry wood and teak wood marine furniture, yacht interiors and accessories. Bay Area Marine has been fabricating custom yacht interiors and furniture since 1993 with pride, integrity and quality craftsmanship.